The dies of tablet presses are big new parts of machines. There are many different types and shapes of coatings available, each helping to create a way to tablet. Through this text, we will learn about the different and crucial components of tablet making, the accurate processes involved in tablet making, the different dies that can be used for various tablet shapes and formulations, the durability of components involved in tablet making, and how new materials helping in improvement of manufacturing processes for tablets.

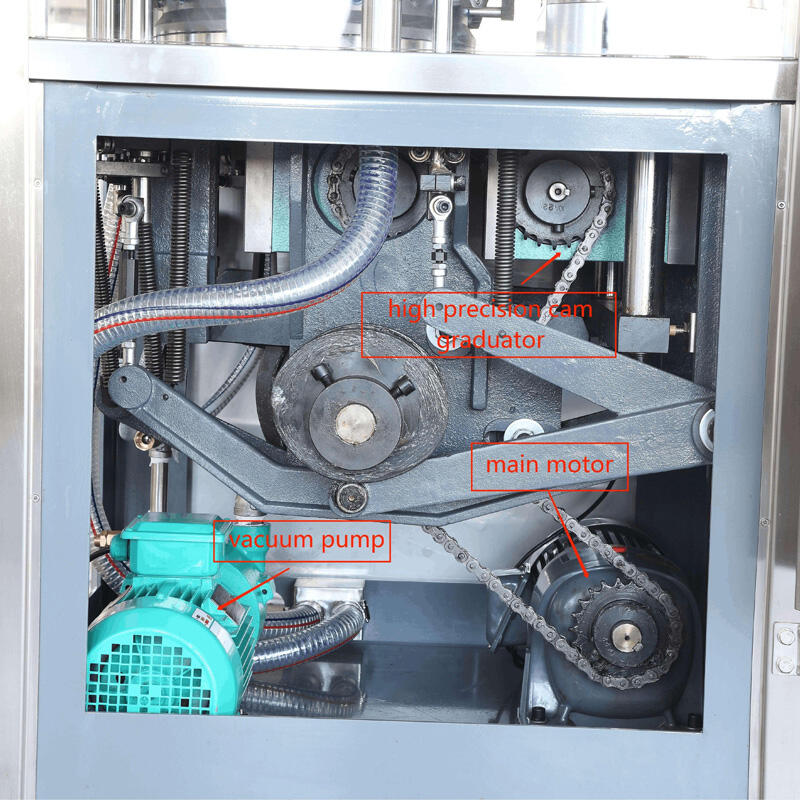

The pill tablet press are a very important part of the process of making tablets. They shape the tablets into the many unique shapes and sizes before they make it to the store. The key components specify a feeding system; a die system; a compression system; and an ejection system.

Each of these machines has a unique enclosure called a hopper that feeds the machine with mini pieces referred to as granules. These granules essentially form the constituents of the tablets. When the hopper is full, the granules flow into the die system, which is the area where the tablet die exists. The compressed granules are then compressed into a solid tablet using a powerful hydraulic press. The ejection system pushes the tablets out of the die once they are pressed and sends them on to the packaging area, where they are prepared for shipping.

For reasons that don't need to be repeated here (if you're reading this, I assume you already know), tablet drugs need to be shaped correctly, which means tablet press machine need to be made with great care. The correct dies are extremely important because the tablets must always be of the same size and weight. Engineers use cutting-edge computer programs to create a 3D model that will help create this special dies. Next, this model is transformed into an exact plan that allows us to produce the die in specialized, precision machines. This meticulous process is critical because it ensures the dies are properly shaped to create impeccable tablets each time they are utilized.

Tablet press dies can be designed and manufactured in different shapes and types so that the tablet production requirements can be adequately served. It also means that the dies can be modified to produce tablets of whatever shape, size, or weight. The fact that the dies can be easily altered is of great assistance to manufacturers, as it enables them to promptly transition between different tablet designs without requiring an additional machine. Having this flexibility is crucial as it allows manufacturers to make multiple tablets on the same equipment, reducing time and resources.

Tianfeng tablet press dies are highly durable. Each machine used for making these tablets is made from high-quality, sturdily designed raw material that can survive the intense demands of making tablets on a daily basis. These dies are wear-resistant and are capable of working under high pressure without cracking or deforming. Tablet yesterday) Production can continue uninterrupted because they are built to do so. This means the cameras can run longer and produce more tablets without needing repairs or maintenance — driving down costs.

Tablet press dies are also utilized to enhance efficiency in the tablet manufacturing process. This paves the path for newest approaches - new materials and design that decrease the potential of defects with in the tablets resulting in a better quality. The materials used for making these dies are resilient steels, carbides, and wear walls. However, the dies are optimally designed to weigh out both size of tablets, thus requiring minimal manual inspection for quality. These innovations help the manufacturing process faster and cheaper, meaning manufacturers can produce more tablets for less.

We not only occupy an important position in the domestic market, but also actively explore the international market, and our products are exported to Southeast Asia, Europe and the United States. With our keen insight into global market trends and localized service capabilities, we are committed to becoming an international leader in the tablet press field.

We have comprehensive technical capabilities in the field of tablet presses, covering all technologies related to tablet production, from tablet presses to auxiliary equipment, tableting mold design, etc. Our products are widely used in dozens of production fields such as Chinese medicine tablets, Western medicine tablets, buccal tablets, effervescent tablets, disinfection tablets, fertilizer tablets, pesticide tablets, electronic components, etc.

Our products are not only distributed throughout the country, but also exported to Southeast Asia, Europe and the United States, and are gradually expanding the global market. With reliable product quality and high-quality services, we enjoy a good reputation in the market and have won the trust and support of domestic and foreign customers.

We focus on the innovation and R&D of tableting technology, and can provide customized tableting solutions according to the special needs of customers. Whether it is tablet shape, size or production process, we can provide flexible design and production services to help customers achieve efficient and accurate production goals.