Mechanical part:

● variable frequency motor and synchronous toothed belt are used to drive the reducer in the main transmission system. The reducer drives the gear pair, and the ring gear drives the punching plate to rotate. The main motor adopts variable frequency speed regulation, and the output is continuously adjustable in a wide range;

● the machine body frame is made of cast iron, which makes the machine run more smoothly;

● the combined upper guide rail is designed to facilitate disassembly, maintenance and replacement. The double-sided lifting guide rail is selected, with uniform force on the punch and long service life;

● rely on the hydraulic system to provide stable and reliable system support;

● the centralized lubrication system (dry oil lubrication system, thin oil lubrication system and circulating lubrication system) provides sufficient lubricant to all lubrication parts through automatic control to ensure the safe operation of the machine;

● the tablet pressing process adopts secondary pressure forming. The pre pressing wheel and the main pressing wheel are adjusted independently, and the super large pressing wheel can obtain the best pressing time for the produced tablets;

● new high-precision pressure detection system enables on-line monitoring of main and pre pressure, so as to control various technical indexes required by tablets;

● new design of powder retaining mechanism to make full use of materials;

● detection devices such as punch running too tight and main pressure overload can effectively protect equipment and molds from damage. The setting of various safety detection systems enables the equipment to provide effective protection for personal safety during operation;

● all parts in contact with the powder shall be made of materials meeting the requirements of drug hygiene, the upper and lower punching holes shall be provided with special dust and oil proof sealing protection, and the tablet pressing chamber shall be fully sealed to make the equipment comply with GMP specifications;

● the equipment shall be placed on the shockproof foundation to avoid transmitting vibration to adjacent equipment during operation;

● the whole machine has beautiful design, fine workmanship and convenient operation;

Electric control part

GZPT series automatic high-speed rotary tablet press is equipped with a special operation control system for this series of models. The system provides intuitive data display for users, and the large color touch screen makes all production data obvious. Using the special software of this machine, it is very easy to set the position of up and down impact, as well as the pressure required for main pressure and preloading. Users can continuously adjust the film weight and thickness online, and can be clearly displayed on the touch screen.

| Model | GZPT-15 | |

| No. of Stations | 15 | |

| Type of Tooling | D | |

| Max. Pressure (kN) | 100 | |

| Max. Pre-pressure (kN) | 12 | |

| Max. Tablet Diameter (mm) | Round tablet | 25 |

| Special shaped tablet | 25 | |

| Max. Filling Depth (mm) | 20 | |

| Max. Tablet Thickness (mm) | 6 | |

| Upper and Lower punch Length (mm) | 133.6 | |

| Upper and Lower punch diameter (mm) | 25.35 | |

| Middle Mold Diameter (mm) | 38.1 | |

| Middle Mold Height (mm) | 23.81 | |

| Max. Tablets output (pcs/ hour) | 70000 | |

| Max. Turret Speed (1/min) | 11-70 | |

| Main Motor Power (kW) | 5.5 | |

| Height of the Machine (mm) | 1850 | |

| Machine Floor Space (mm²) | 1100×950 | |

| Machine Net Weight(kg) | 675 | |

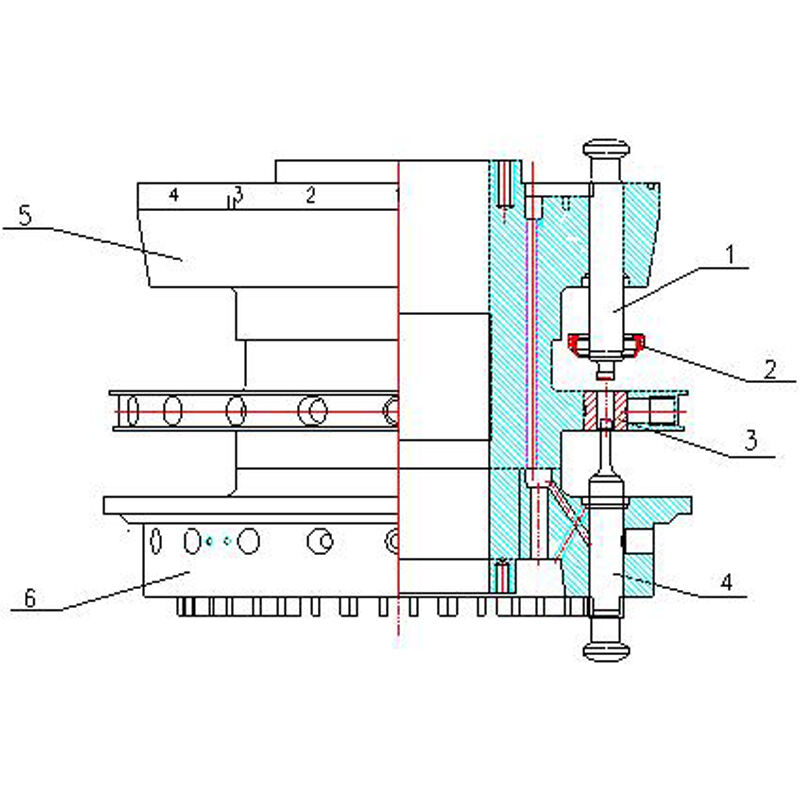

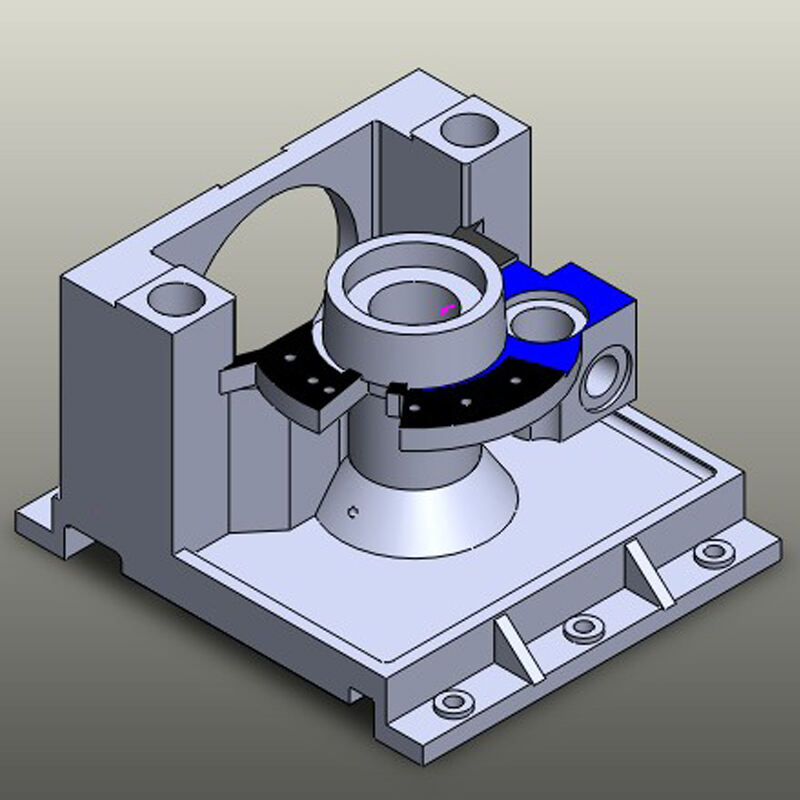

The main structure of the machine is mainly composed of the base, front and rear support, worm wheel box, seat body, punching plate, support block, roof plate, glass door, upper cover body, control cabinet and other parts. The base, front and rear supports and seat body are bolted to form a solid frame, as the basis of the tablet press. The worm wheel box is fixed on the present body, based on the seat body, the outer cam, block, lower guide rail cam, filling regulating mechanism, prepressure guide rail and lower main pressure wheel are installed on the present body.

● The support block is connected with the chassis through the left and right column pull rod, forming a stable frame structure. This casting has extremely high bending and torsion resistance, which meets the bearing requirements of the tablet press. The support block is equipped with guide rail plate, lower pressure cam, upper prepressure wheel and upper main pressure wheel. The upper roof plate is installed on the upper part of the support block, between the upper roof plate and the supporting block. The four sides of the top roof contain four glass doors. Each glass door is covered with air springs that provide support and locking force for the opening and closing of the glass doors.

● From the function of the platform as the boundary can be divided into the upper and lower two parts.

The upper part of the press is a fully sealed press chamber, which is the part of the whole press process. It includes the forced feeding system, stamping combination, release device, dust suction system. The press chamber is completely sealed by the roof, cover plate and glass door through the sealing strip to prevent the external pollution of the press process.

The lower part of the tablet press is equipped with the main transmission system, lubrication system and translation adjustment mechanism, including the rear door, left and right doors and control cabinet through the sealing strip to prevent dust pollution to the machine.

1. Vacuum feeding machine

Bucket sensor and PLC program achieve automatic feeding effect without manual adjustment.

2. Batch clear waste

Waste products are eliminated in batches through program control or manual selection, so that tablets with unqualified quality are discharged from the designated material port.

3. Automatic adjustment of film weight

After the warehouse is stable, the automatic tablet weight adjustment function can be turned on to ensure that the weight difference of the entire batch of medicines is within the required range without manual intervention.