Answer: Tablet are small round things that are meant to take to feel healthy when sick or not well. People sometimes have to take a lot of tablets each and every day to help them get better. But before anyone can take a tablet someone has to make it! This is all where a special machine called a single punch machine comes in It is a critical machine for the production of our required tablets.

Similar to the tablet press, a single tablet press is a special type of machine that is used to make tablets. And the great thing about this machine is that it can produce many tablets at the same time! This is very useful for medicine-generation companies. Rather than take a long time to make one tablet by hand, they can produce hundreds or thousands of tablets in no time with the single tablet press.

That process saves time and money because they don’t have to repeatedly stop and start in tablet making. Instead, the device can continue operating until they prepare sufficient tablets. When they get a big enough pile of tablets, they box them all up and ship them off to the pharmacy. That is why when you are sick, you can head to the pharmacy, get the medicine you want to feel better.

This allows for larger quantities of medicine to be produced in a shorter period of time. It also guarantees that every tablet you take will contain the exact same amount of each medicine that’s supposed to be in it. This is quite relevant for your health, because this guarantees that you are receiving the appropriate amount.

There are several benefits for manufacturers using a single punch tablet press that all point to it being a viable option. For instance, it is considerably quicker than producing tablets manually. The machine does not require long periods of time to make tablets. It is also more precise — less of a chance to make an error in tablet manufacturing.

Other conditions and advantages are that these machines can also produce tablets that come in various sizes and shapes. That means that companies can manufacture medicine that is easier to swallow. Some people have a whole lot easier time taking tablets that are smaller or differently shaped. They can also make special tablets that stay longer in your body, which means you don’t have to take as many of them during the day.

To sum it up, single tableting machines are impressive machines that can produce a ton of tablets in one go! They transformed the way medicine is manufactured, making it less expensive and more widely available. These machines are not only faster but also more accurate than handmaking tablets, which is vitally important for your health.

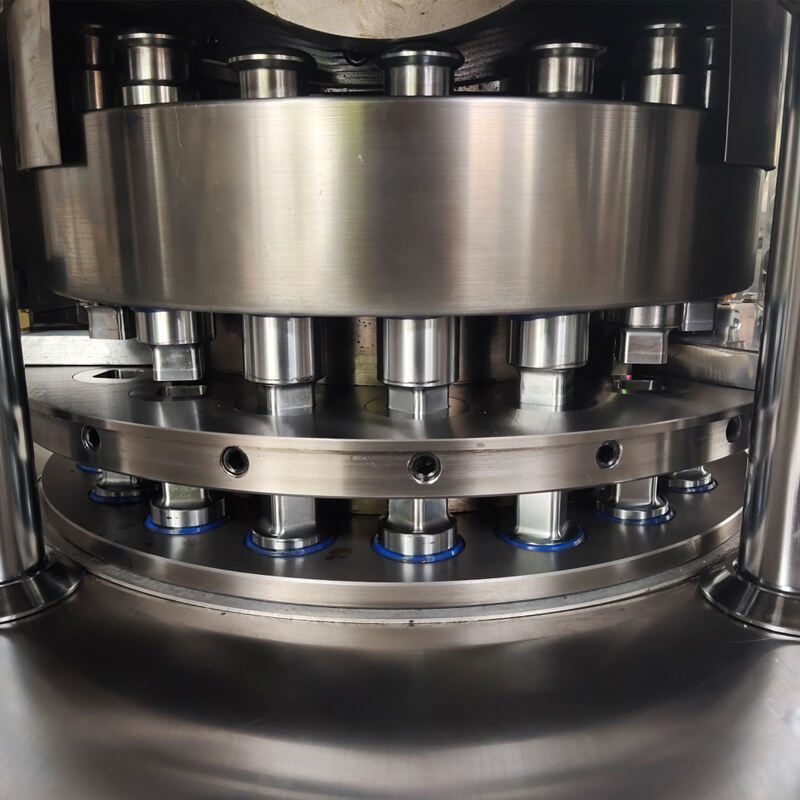

We have comprehensive technical capabilities in the field of tablet presses, covering all technologies related to tablet production, from tablet presses to auxiliary equipment, tableting mold design, etc. Our products are widely used in dozens of production fields such as Chinese medicine tablets, Western medicine tablets, buccal tablets, effervescent tablets, disinfection tablets, fertilizer tablets, pesticide tablets, electronic components, etc.

Our products are not only distributed throughout the country, but also exported to Southeast Asia, Europe and the United States, and are gradually expanding the global market. With reliable product quality and high-quality services, we enjoy a good reputation in the market and have won the trust and support of domestic and foreign customers.

We not only occupy an important position in the domestic market, but also actively explore the international market, and our products are exported to Southeast Asia, Europe and the United States. With our keen insight into global market trends and localized service capabilities, we are committed to becoming an international leader in the tablet press field.

We focus on the innovation and R&D of tableting technology, and can provide customized tableting solutions according to the special needs of customers. Whether it is tablet shape, size or production process, we can provide flexible design and production services to help customers achieve efficient and accurate production goals.