Have you have ever wondered how they get things like pills and gum into those little plastic bubbles that you pop open? It’s really interesting! This incredible job is performed by a device known as a blister machine. Let’s learn more about it!

It is a special type of machine known as a blister machine. It assists companies in designing the packaging that protects their products and offers it with an easy way to use. It does this by heating a piece of plastic. Next, it molds the plastic into a bubble. Then it takes that bubble and seals it with the product inside. That way, the product remains protected until you are ready to use it!

So when you run a business, you do understand the necessity to pack your products nicely and market them well. That is where a blister machine comes to use! With a blister machine, you can ensure your products are packaged and easy to use for your consumers.

Not only does this make your products look good and more appealing to your customers, but it can help you save money in the long run. With a blister machine in hand, you can enhance the packing speed and be more efficient while doing it. That is to say, you can push out more products out the door and into the hands of your customers quicker than before!

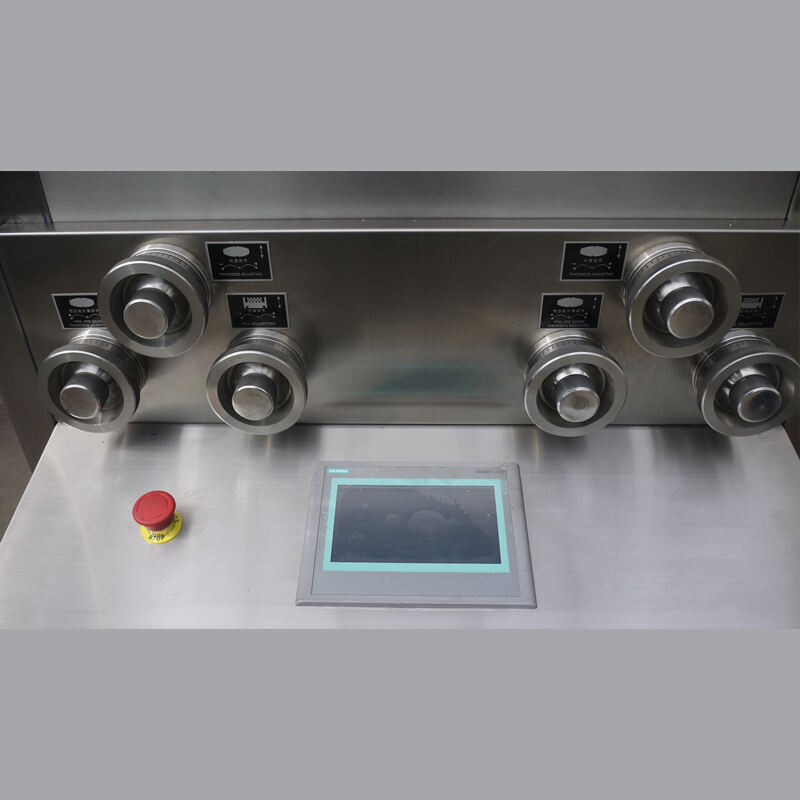

From the outside blister machines might look simple, but in fact are utilizing a many smart technology to ensure right work. For instance, they give you specially made rollers that will heat the plastic as you perfectly mold it into a bubble. They also have sensors that ensure the product is correctly position before the plastic is sealed shut.

Overall, you do have to clean the machine regularly to keep it from becoming dirty and dusty. You also want to ensure all parts that are moving parts are greased and lubricated to let them work smoothly. You also need to inspect the sensors and change any degraded or damaged components.

There are some steps that you can take to ensure you are getting the most out of your blister machine. One nice way to speed up your packing process is to use pre-packaged products. One good idea is to use a conveyor belt to handle the product rapidly between machines.

Our products are not only distributed throughout the country, but also exported to Southeast Asia, Europe and the United States, and are gradually expanding the global market. With reliable product quality and high-quality services, we enjoy a good reputation in the market and have won the trust and support of domestic and foreign customers.

We focus on the innovation and R&D of tableting technology, and can provide customized tableting solutions according to the special needs of customers. Whether it is tablet shape, size or production process, we can provide flexible design and production services to help customers achieve efficient and accurate production goals.

We not only occupy an important position in the domestic market, but also actively explore the international market, and our products are exported to Southeast Asia, Europe and the United States. With our keen insight into global market trends and localized service capabilities, we are committed to becoming an international leader in the tablet press field.

We have comprehensive technical capabilities in the field of tablet presses, covering all technologies related to tablet production, from tablet presses to auxiliary equipment, tableting mold design, etc. Our products are widely used in dozens of production fields such as Chinese medicine tablets, Western medicine tablets, buccal tablets, effervescent tablets, disinfection tablets, fertilizer tablets, pesticide tablets, electronic components, etc.