Do you want to develop meds capsules. It used to be done with great difficulty, but today there is a special machine, with the help of which, you can do everything quickly and easily! Well, this thing is an incredible 400 Holes Capsule Filling Machine. Follow along and discover how this device can assist you in speeding up and improving the way you make your capsules!

Making medicine capsules was a time-consuming and difficult process before this machine was invented. It was labor-intensive, as each capsule had to be filled by hand, which could take hours. But now, we have the 400 Holes Capsule Filling Machine, making hundreds of capsules within 1-5 minutes! Since it is also a time-consuming process, this machine is best for those companies that have medicine capsules in their production line. This machine helps businesses to generate capsules in a very limited time.

That process can be quite time-consuming, but with a 400 Holes Capsule Filling Machine, you can easily create hundreds of capsules in a timely manner. Such speed saves time and money for your business. That's right, being able to fill a ton of capsules within so little time means you can now concentrate on other things that matter in your business!

Another great reason to use this machine is that it is extremely accurate. It is not easy to ensure that each capsule contains an equal proportion of the medicine when you produce capsules by hand. At times some of the capsules may contain excess medicine, while some may have too little. This can be bad for customers requiring the right dose. However, with the capsule filling machine, you can guarantee to have each capsule to have the exact amount of medicine present. This ensures that your customers receive the right dose each time which is critical for their health and safety.

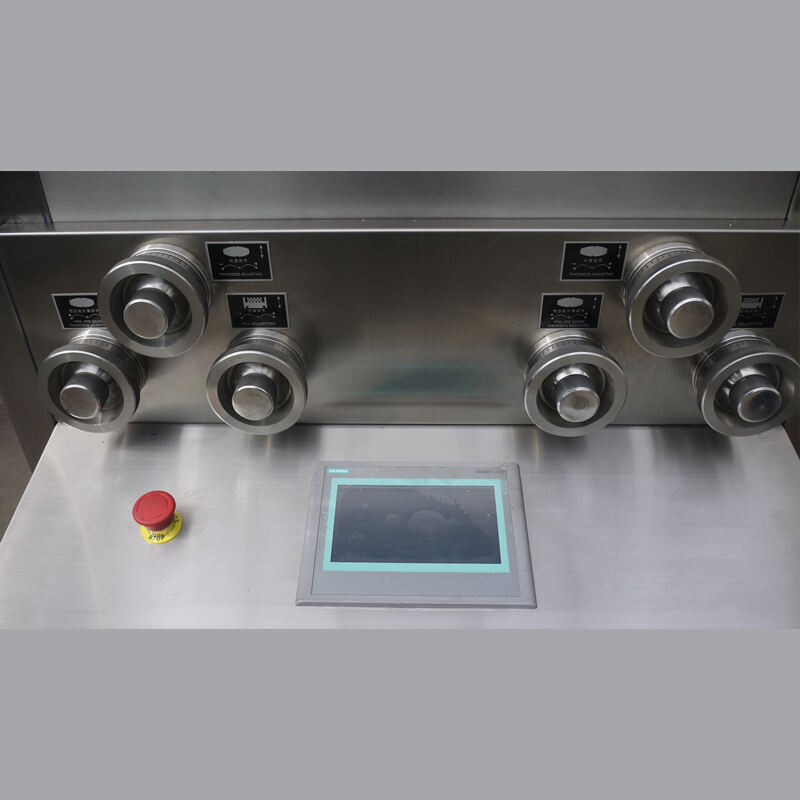

If you choose to order a 400 Holes Capsule Filling Machine from Tianfeng, you will get a robust and durable machine you can use for decades. Well built using durable materials that can take the heat from heavy use. Its also very easy to clean, so you will not have to worry about spending hours keeping it clean.

The 400 Holes Capsule Filling Machine may help save your production line. It accelerates the entire process and makes it more accurate, which saves you time and money. This machine is designed for heavy fabrication and high demands, making it an excellent investment for your business as it's made to last.

This machine allows you to prepare more medicine capsules in a shorter amount of time. We train on data until October 2023, Eva this allows your business to expand and serve more customers, which is vital for the success. When your company is able to produce more capsules faster and more accurately, the demand for those who rely on your products will be catered to on a larger scale.

Our products are not only distributed throughout the country, but also exported to Southeast Asia, Europe and the United States, and are gradually expanding the global market. With reliable product quality and high-quality services, we enjoy a good reputation in the market and have won the trust and support of domestic and foreign customers.

We not only occupy an important position in the domestic market, but also actively explore the international market, and our products are exported to Southeast Asia, Europe and the United States. With our keen insight into global market trends and localized service capabilities, we are committed to becoming an international leader in the tablet press field.

We have comprehensive technical capabilities in the field of tablet presses, covering all technologies related to tablet production, from tablet presses to auxiliary equipment, tableting mold design, etc. Our products are widely used in dozens of production fields such as Chinese medicine tablets, Western medicine tablets, buccal tablets, effervescent tablets, disinfection tablets, fertilizer tablets, pesticide tablets, electronic components, etc.

We focus on the innovation and R&D of tableting technology, and can provide customized tableting solutions according to the special needs of customers. Whether it is tablet shape, size or production process, we can provide flexible design and production services to help customers achieve efficient and accurate production goals.