Have you ever wondered how your medicine ends up in those tiny capsules? It may look like magic, but there’s in fact a special machine that aids the process. We are here today to study the 100 Holes Capsule Filling Machine to fill 100 holes with medicine in no time! It is also a big deal for large pharmaceutical manufacturers, such as Tianfeng, because this machine will allow them to produce more products and keep an eye on healthy patients.

If you make something like medicine, and you need to produce a huge amount of it in a short period of time, you recognize how important it is. That's where the 100 Holes Capsule Filling Machine comes in! It can fit 100 holes with medicine in a matter of minutes. That means your company can produce more medicine overall, enabling you to provide aid to more people in need of it. With the power of this machine, you can fill hundreds of capsules in the time that it takes to fill a few capsules by hand!

You want your product to be safe, effective and of the highest quality as a company that makes medicine. All of this important points are taken care of, by 100 Holes Capsule Filling Machine. It is meant to help minimize the likelihood of germs and other unwanted things getting into the medicine. That way each capsule will contain the right amount of the medicine. This machine provides information confirming that your products meet high standards which is vital information for the health of the people that will consume your products.

For businesses that manufacture medicine, the 100 Holes Capsule Filling Machine has various benefits. For example, one of the main advantages is that it saves money on the filling of capsules of medicine. This machine has eliminated the need for time-consuming manual filling, which also comes with high chances for errors. The machine is also designed without many interlocking parts, which makes it easy to operate, so workers don’t have to undergo extensive training to use it. In addition, it can accommodate a variety of filling materials, including powders and small pellets making it very versatile and ideal for a wide range of medicines! This versatility helps reduce time and energy on any product that you're creating. When you purchase a machine from Tianfeng, you can rest assured you’re getting a solid, trusted machine that’s going to last you a long time — you won’t need to replace it any time soon.

The challenge businesses are having is how to do their work efficiently. The 100 Holes Capsule Filling Machine Fill the capsule automatically, ease your work. All it does is fill 100 holes at once, instead of having to fill each capsule individually by hand, which takes so much time and effort. That means the work goes faster, and it does a better job at ensuring every capsule is filled, Wright said. Moreover, with a simple design, the machine requires less time to spend on training and maintenance. With this, companies have the luxury of working on other significant activities, and the machine can manage the filling process.

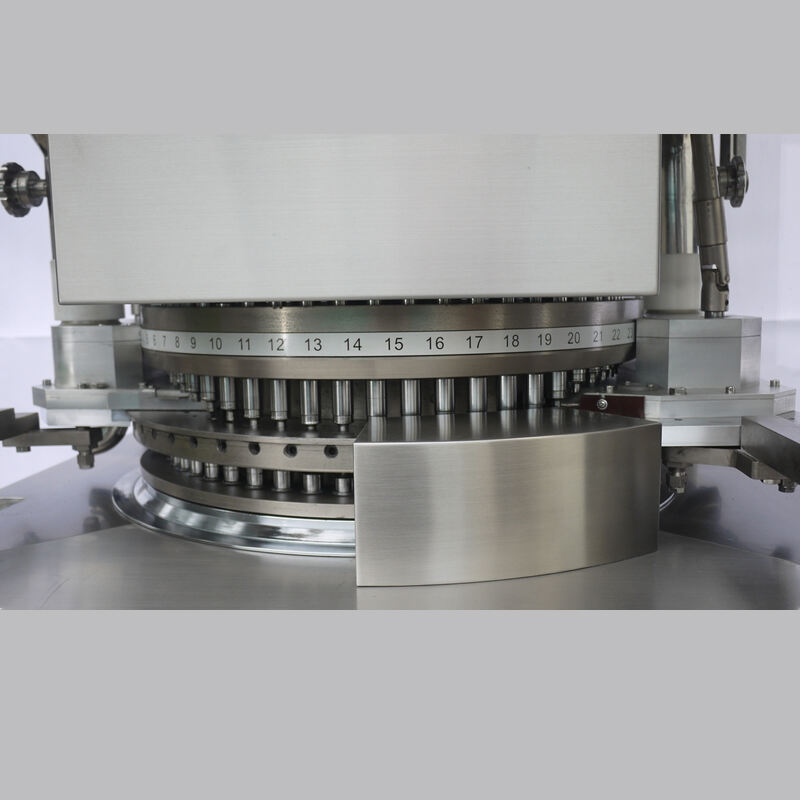

We have comprehensive technical capabilities in the field of tablet presses, covering all technologies related to tablet production, from tablet presses to auxiliary equipment, tableting mold design, etc. Our products are widely used in dozens of production fields such as Chinese medicine tablets, Western medicine tablets, buccal tablets, effervescent tablets, disinfection tablets, fertilizer tablets, pesticide tablets, electronic components, etc.

Our products are not only distributed throughout the country, but also exported to Southeast Asia, Europe and the United States, and are gradually expanding the global market. With reliable product quality and high-quality services, we enjoy a good reputation in the market and have won the trust and support of domestic and foreign customers.

We focus on the innovation and R&D of tableting technology, and can provide customized tableting solutions according to the special needs of customers. Whether it is tablet shape, size or production process, we can provide flexible design and production services to help customers achieve efficient and accurate production goals.

We not only occupy an important position in the domestic market, but also actively explore the international market, and our products are exported to Southeast Asia, Europe and the United States. With our keen insight into global market trends and localized service capabilities, we are committed to becoming an international leader in the tablet press field.