Tablets are an easy and cleaner alternative for taking medicine and vitamins. It can take many different shapes and sizes and also different colors. Yes, you may have seen round, oval or even square tablets, some as bright a color as blue or pink. But do you know how they make these tablets? The pill tablet press is a special machine used to increase the tablets in the right way. This machine plays a very crucial part in the tablet manufacturing process.

One specialized type of machinery, the hammer tablet press, compresses powders or tiny granules into tablets. This is a great big machine with lots of different pieces that come together to make these tablets. Another is the part known as the feeder. The powders that will become tablets are added to the machine by the feeder. You can think of the feeder as a big bucket that dumps the powder into the machine so that it is prepared to be pressed.

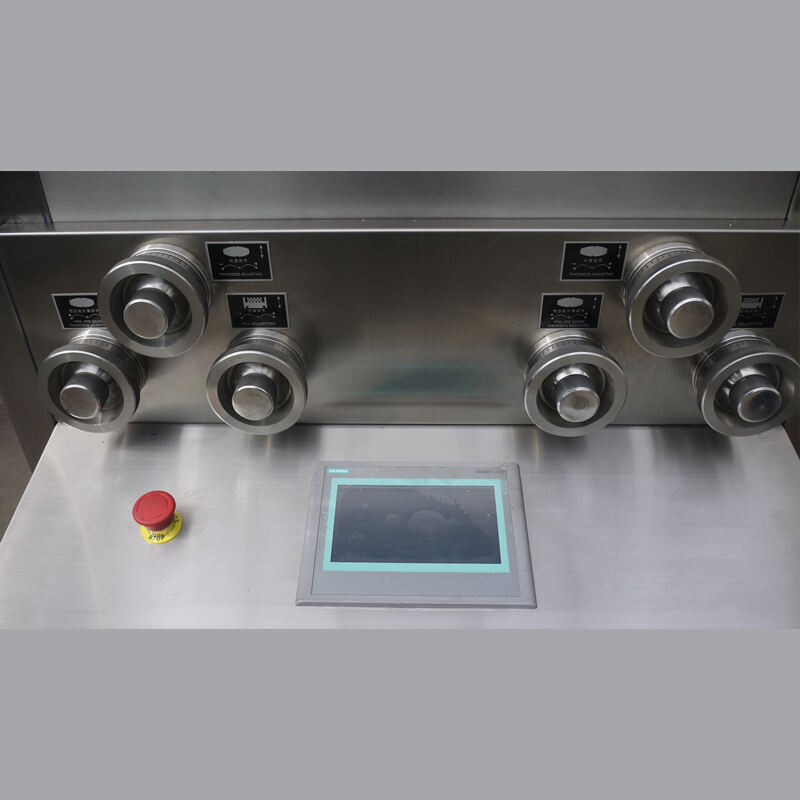

The machine has a part known as the hopper. The powder is stored in the hopper before it passes to the feeder. It acts as a khojenagen storage room for the powder. After that, the powder enters the feeder and is compressed to a required tablet volume by two key players: the punch and the die. As it descends, the punch works like a hammer, driving the powder down into the die. The subject, the die, is a mold which compresses the powder or granules into a cohesive solid tablet. It's an important step in making tablets of the proper shape and size.

Advanced knowledge and attention to detail is essential when using the filling machine of capsule. Poor setup of the machine, may result in non-uniform and low BS tablets. The tablets can’t be done well without proper setup of the machines. The hammer type tablet press would downside would be, you have to monitor the amount of pressure used while pressing the powder. The amount of pressure is key and making sure it is just the right amount. If you put too much pressure on it, the tablet can crack or shatter. But if you don’t press hard, the tablet could be too soft and may crumble too easily.

It is a very high speed tablet press machine. Within a brief period of time, it can manufacture multiple tablets, with the ability to yield thousands of tablets hourly! The apparatus is built for speed and precision. This means that every tablet is of consistent size and shape as a result of the hammer tablet press being so precise and being able to compress the powder or granules into the same spots every time. This consistency is critical for how we utilize and package the tablets. Uniformity in tablets ensures that each tablet contains its correct dose of medicine or vitamins.

The hammer tablet press is a versatile machine that can found in many different industries. It assists in the manufacturing of tablets of many types. In the pharmaceutical industry, it makes significant tablets like vitamins, antibiotics and pain relievers. Those are medicines that make it feel better when people are sick, or hurt.

The hammer tablet press is utilized to produce delicious food products such sugar tablets and mints. These Tablets are fun to consume and are available in delicious Flavors. Even in the chemical industry, this machine useful. This is used to produce a variety of cleaning tablets and agricultural tablets that assist on an agricultural basis and ensure the cleanliness of our abode.

We not only occupy an important position in the domestic market, but also actively explore the international market, and our products are exported to Southeast Asia, Europe and the United States. With our keen insight into global market trends and localized service capabilities, we are committed to becoming an international leader in the tablet press field.

Our products are not only distributed throughout the country, but also exported to Southeast Asia, Europe and the United States, and are gradually expanding the global market. With reliable product quality and high-quality services, we enjoy a good reputation in the market and have won the trust and support of domestic and foreign customers.

We have comprehensive technical capabilities in the field of tablet presses, covering all technologies related to tablet production, from tablet presses to auxiliary equipment, tableting mold design, etc. Our products are widely used in dozens of production fields such as Chinese medicine tablets, Western medicine tablets, buccal tablets, effervescent tablets, disinfection tablets, fertilizer tablets, pesticide tablets, electronic components, etc.

We focus on the innovation and R&D of tableting technology, and can provide customized tableting solutions according to the special needs of customers. Whether it is tablet shape, size or production process, we can provide flexible design and production services to help customers achieve efficient and accurate production goals.