A specialized tool, blister packaging machine enables businesses to maintain the security and organization of their products. Small and medium-sized companies in search of a smart and cost-effective product packaging solution will find such equipment very beneficial. It ensures that goods are packaged tightly so they aren’t damaged in transit before arriving to customers.

The most significant benefit of blister packaging equipment is its ability to save businesses money. This means that companies can package their products a lot faster than if they were doing it all by hand. The mice type increase in speed means that businesses don’t need to pay as many workers to do something, which is a way for a business to reduce or eliminate labor costs.

Another advantage of blister packing machine is that it enables businesses to operate more quickly and effectively. Using this machine, they can prepare their products for the market in no time. It saves time by freeing workers from packaging products. With automated packaging, businesses can empower employees to do their jobs more effectively and efficiently.

Use Of Blister Packaging Machines– One of the greatest advantages to the advanced blister packaging machines is that they do the whole packaging at rapid speed. Because these machines are designed for maximum efficiency, businesses are able to package more items in less time. That means they get their products to customers quicker, which can drive sales up.

There are many benefits of using automated blister packaging technology but one of the major advantages is being able to pack a product at a much faster speed than packing a product manually. Human beings are bulky and their maneuverability is limited and therefore relying on people to do that job takes way longer than technology can do.

Therefore, this equipment plays a critical factor in business functionality and needs to be chosen wisely. When choosing the appropriate machinery, there are several variables that businesses need to consider. They should think about the size and specs of their products, how much they want to automate the process and how much money they have to spend.

The business also needs to decide how much of the packaging process it would like to automate. No proper packaging solution will work for every company; some companies desire to automate their entire packaging line while others only want to automate portions and some will merely stick to manual packaging. Understanding these needs will enable them to select the appropriate equipment for their situation.

We not only occupy an important position in the domestic market, but also actively explore the international market, and our products are exported to Southeast Asia, Europe and the United States. With our keen insight into global market trends and localized service capabilities, we are committed to becoming an international leader in the tablet press field.

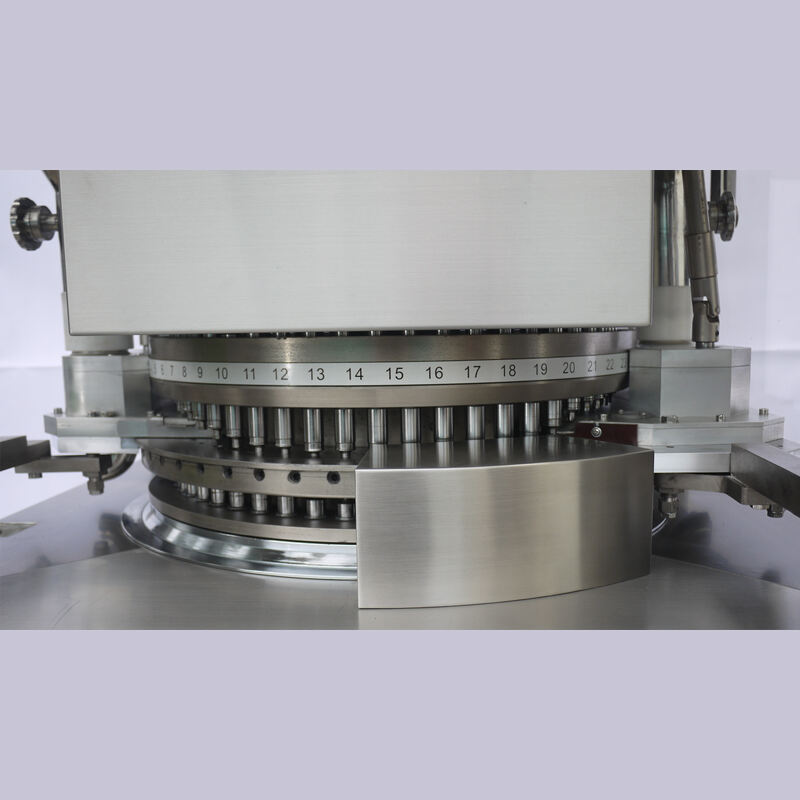

We have comprehensive technical capabilities in the field of tablet presses, covering all technologies related to tablet production, from tablet presses to auxiliary equipment, tableting mold design, etc. Our products are widely used in dozens of production fields such as Chinese medicine tablets, Western medicine tablets, buccal tablets, effervescent tablets, disinfection tablets, fertilizer tablets, pesticide tablets, electronic components, etc.

Our products are not only distributed throughout the country, but also exported to Southeast Asia, Europe and the United States, and are gradually expanding the global market. With reliable product quality and high-quality services, we enjoy a good reputation in the market and have won the trust and support of domestic and foreign customers.

We focus on the innovation and R&D of tableting technology, and can provide customized tableting solutions according to the special needs of customers. Whether it is tablet shape, size or production process, we can provide flexible design and production services to help customers achieve efficient and accurate production goals.