This machine is mainly used for vacuuming equipment which is easy to produce mechanical equipment in industrial production. This machine is produced in an industrial environment, with a granulator, a tablet press, a tablet making machine and a grinder. Native matching. Made of stainless steel material, it has good anti-corrosion ability and will not produce the generated substances. Therefore, the various recovery of the generated sound is in line with GMP and adopts the elimination device, which is required to reduce the impact.

| Model | Units | DSN 22 | DSN 30 | DSN 40 |

| Vlots | V/Hz | 380V 50HZ 3P, 415V 50HZ 3P, 220V 60HZ 3P | ||

| Power | Kw | 2.2 | 3.0 | 4.0 |

| Vacuum | Kpa | 22 | 26 | 28 |

| Airflow | M³/h | 320 | 380 | 410 |

| ASLL | S/F/D | Back blowing and cleaning | ||

| Filter | m² | 3.67 | ||

| Noise | Db(a) | 64 | 69 | 69 |

| Suction Port | Mm | ¢50 | ||

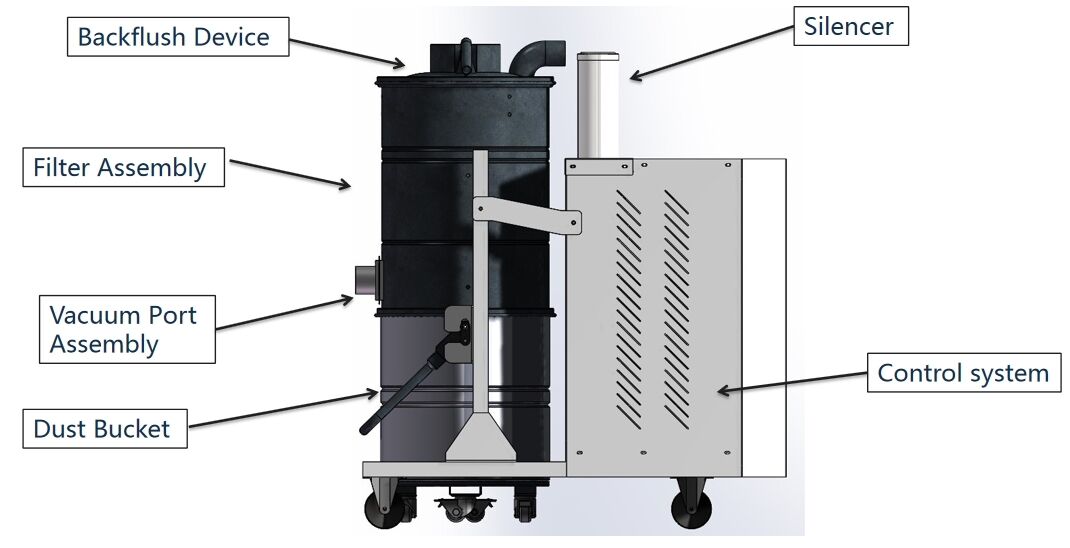

1. The power of the vacuum cleaner is a three-phase industrial high-pressure fan, which has large suction, low noise, no vibration, and can run for a long time.

2. The cleaning method is optional Back blowing cleaning, effective cleaning, prolonging the service life of the filter cartridge

3. The filter material uses a dust filter cartridge to isolate dust particles.

4. Equipped with a pressure relief device, which can automatically release pressure in the case of high negative pressure

5. The dust collecting bucket adopts the upper and lower separation structure for locking, which is convenient and quick to assemble, disassemble and wash.

6. Vacuum pressure gauges and silencers.

7. Overload, overcurrent, phase loss, leakage protection system

8. Equipped with a phase inversion switch, the electricity consumption is safer and faster

9. The base of the fuselage is equipped with a universal wheel, using a 304 stainless steel bracket, which can be rotated 360° for braking. The overall structure is beautiful and durable, and it is light and convenient to drive.

Main frame:

2mm thickness 304 stainless steel square tube structure

Chassis:

1.2mm thickness 304 stainless steel sheet metal

Dust bucket:

1.2mm thickness 304 stainless steel anti-corrosion treatment

The CNC spinning mold is formed at one time, which is durable and beautiful in appearance.

Simple structure, convenient operation, easy maintenance.

High safety factor, safe electrical control.