An Overview of How a Rotary Tablet Press Works

Have you ever considered how those tiny tablets you down when feeling sick are produced? They are produced using a device known as a rotary Tablet Press Tooling. Let’s find out how the dishwasher is designed to work — and what sets it apart.

Looking in the Machine to Inside of the Rotary Tablet Press

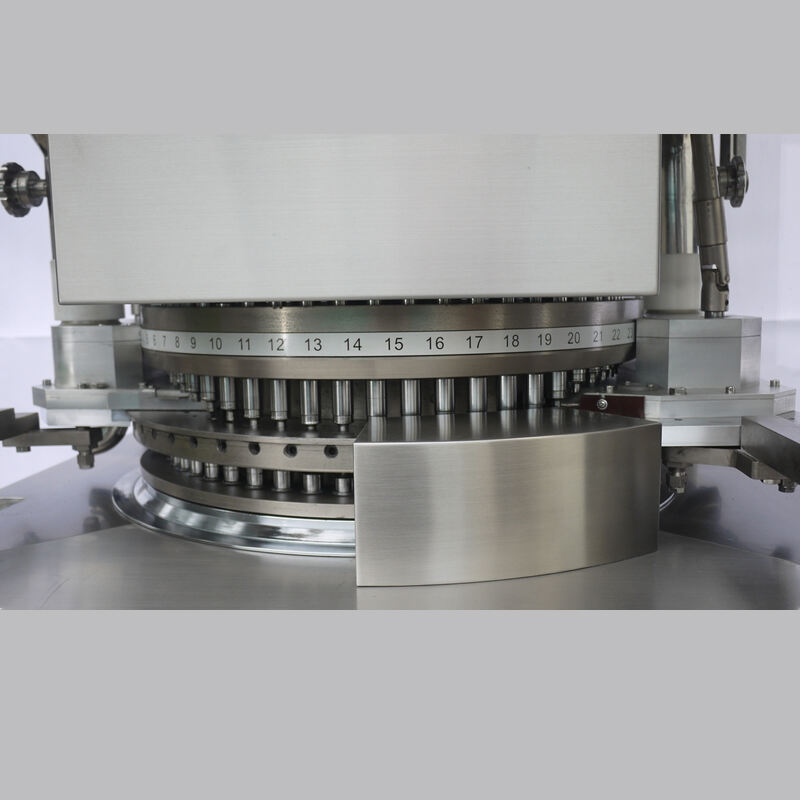

In a rotary Tablet Press , there are plenty of components that come together to make those little tablets. One major component is the hopper, which contains the powder that will become the tablets. Next, the feeder pushes the powder into the die cavity. The die cavity is the place where powder is compressed into the form of a tablet. Last, there is the turret, which contains the punches that squeeze the powder into tablets.

How does Tablets Form in Powder by rotary tablet press?

The powder is migrated to a reservoir separate to the powder reservoir at the time when it is poured into the hopper down the feeder. The powder is subsequently transferred by the feeder into the die cavity and compressed by tools on the turret. The punches rise and fall as the turret turns, compressing the powder into a tablet. It’s interesting how it turns from powder into those small tablets everyone is familiar with.

An Overview of the Major Components of a Rotary Tablet Press

Basic components of a rotary pill tablet press are the hopper, feeder, die chamber, and turret. Now, each one of these components is very important in the manufacture of tablets. The powder is stored in a hopper, the feeder moves the powder to the die cavity where it is pressed and the punches on the turret make the tablets. None of these elements could the machine do without.

the efficiency operation of Rotary Tablet Presses

The rotary press efficiency is derived from the smooth running of all its parts. From the hopper the powder is introduced into the feeder and this in turn directs the powder into the die cavity. The turret houses the punches that daisy-cut the powder into tablets, and as the turret revolves, it continues to produce new tablets. It’s a clever system and it results in producing a lot of tablets quickly.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

MS

MS

KA

KA

BN

BN

LO

LO

LA

LA

MN

MN

MY

MY

UZ

UZ

KY

KY