Tablets are small medicinal products with round o oval form and consist of a drug or active ingredient with excipient. These drugs are normally coated from tianfeng, which implies there is a sure layer placed on them. There are a few reasons for coating them like this. First, it beautifies and embellishes the tablets. 2)this will also save the tablets from water and moisture damage. Another purpose of a coating is to aid those who have a hard time swallowing the tablets. This layer is added to the tablets in what is called tablet coating.

The two major types of tablet coatings most widely used are sugar coating and film coating. For a long, long time, we have had tablets coated with sugar. In the production of these tablets, a colored syrup is used to coat the tablet. This syrup is dried to form a insular layer onto the tablet. This coating process can be repeated several times to provide a thicker layer if desired. But film coating is another procedure. Instead of a syrup, a polymer-based thin layer is coated on to the tablet. This is a quick-drying process, the layer also dries fast, and the coating is solid and durable.

Some Tablet Coating Methods

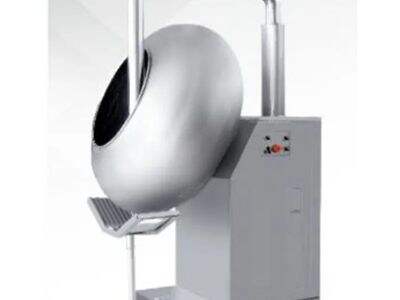

Film Coating – In this process, a particular solution is sprayed onto the Tablet Coating Machine and covered with a thin film. After spraying the material, the tablet is rotated for the removal of excess coating. This forms a fine, polished skin outside the tablet. Not only does this technique makes the tablet glossy in looks, but also protects them from the external environment.

Sugar Coating: Sugar coating is a technique for applying a sugar syrup. They spray this syrup on top of your tablet, and as it dries, you begin to form a coating around the tablet. This process is continued multiple times until the required thickness of the coating is achieved. It not just provides a cover and also layer and protective from moisture and heat to the tablet but also helps the people swallow the tablet with ease.

Enteric Coating: Enteric coating is a method for protecting certain tablets from being dissolved in the stomach. An enteric coating means that a tablet is designed to withstand stomach acid. This implies that the tablet is strong enough to travel the stomach without breaking down and it will only dissolve in the digestive organs rather. This is because it is useful especially in the case of irritating or upsetting drugs for the stomach.

Tablet Coating Solutions for Advanced Applications

Compression Coating – This is a technique of compressing a tablet with one or more layers of coating materials. These could be sugar or specific kind of polymers. The Tablet Packing Machine advantage of this method when compared to conventional sugar coating is related to the number of applications, which is lower since the desired thickness is achieved more quickly.

Electrostatic Coating: This is a method based on utilizing an electric charge to assist with adhering the coating to the tablet surface. The coating consists of charged material that binds to the tablet more effectively. It is a highly effective method since it maximizes the usage of bulk of the coating material with minimal processing wastage.

Spray Drying — This technique involves the formation of a fine powder over the surface of the tablet. This method uses a powder that adheres to the tablet rather than a liquid coating. This is especially beneficial for materials that do not dissolve well in liquid to ensure that the coating of the tablet is effective.

Selecting the Suitable Coating Process

Acquisition of coating method is key to most optimal coating of tablet. One determinant of Tablet Coating Machine is the objective of the coating. What do you need the coat for? The other factor is what the end user wants the tablet to look like. How do you want it to look? Lastly, the evaporation method of coating is also a important factor to considered. Certain coats are needed for some measures to safeguard their substances from moisture or light. By using an appropriate coating, the active ingredients in the tablet get better protection which helps ensuring that medicine will work at the right site at right time.

Comparing Coating Methods

A film-coated tablet is one of the most common digital drug delivery forms. They are made use of more often, as they are a lot more user-friendly and fast-acting than sugar-coated tablets. Moreover, film-coated tablets are less susceptible to environmental impact and the coating film can be made thick or thin as required by the tablet. It is worth mentioning that this approach can be more costly since the film coating materials are typically more expensive.

However, sugar-coated tablets are used for many years now. They have been used for a long time, yet they are slow to manufacture because multiple coatings are required to achieve the needed thickness. This leads to rising production cost. Sugar-coated tablets can actually break and flake easily, this too can make them less potent and less reliable.

These coats can repel the acids and substances of the gastric juices with considerable effectiveness for drugs that must pass through the stomach before they can be absorbed enteric-coated tablets Such a coating is used to protect the medicine against premature degradation. However, enteric-coated tablets are more complex — and potentially more costly — to make. It is important to also store these tablets carefully to keep them effective.

In conclusion, there are different types of advantages of tablet coating method along with disadvantages. Depending on the application of the drug and manufacturing costs, specific method is selected. Choosing the right way to coat the drug is essential to make sure it works and provide the best effects.

Last but not least, Tianfeng is a well-known tablet-coating machine manufacturer. They meet the requirements of the global pharmaceutical industry. Tianfeng has decades of experience and most advanced technology in handling all types of tablet coating with various solutions. Tianfeng specializes in film coating and sugar coating, and their products advocate for quality first, efficiency, and sustainability.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

MS

MS

KA

KA

BN

BN

LO

LO

LA

LA

MN

MN

MY

MY

UZ

UZ

KY

KY